Pressure sensors manufacture

Microtensor is a designer and manufacturer of microelectronic pressure and force sensors and microelectronic pressure transmitters on the base of “Silicon-on-Sapphire” structures. Production was founded in 1980.

Pressure sensors are intended for continuous proportional conversion of pressure or force into electric signal. The main accuracy parameters are nonlinearity, variation and repeatability of the output signal.

Pressure sensors are designed to be applied in pressure transmitters and pressure and force systems in oil and gas industry, mining industry, atomic power engineering, heat metering, industrial automation, hydraulic/pneumatic, pumping stations, compressor, satellite on-board equipment.

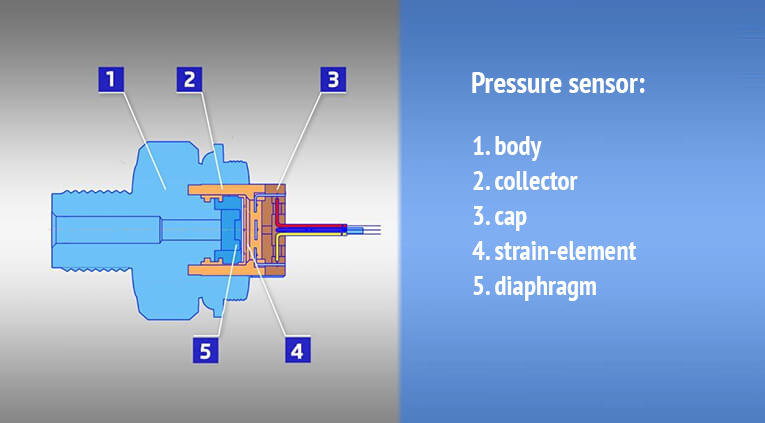

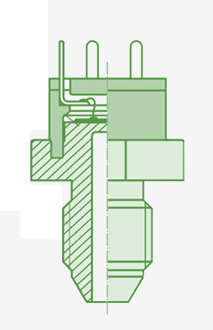

Pressure sensor consists of body, collector, сap, strain-element and diaphragm.

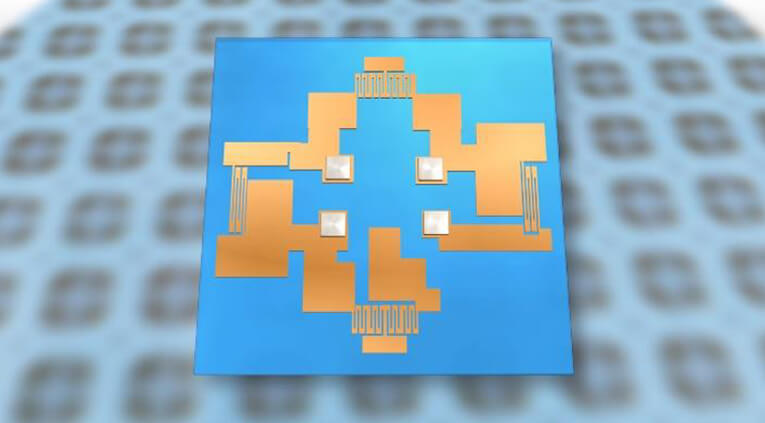

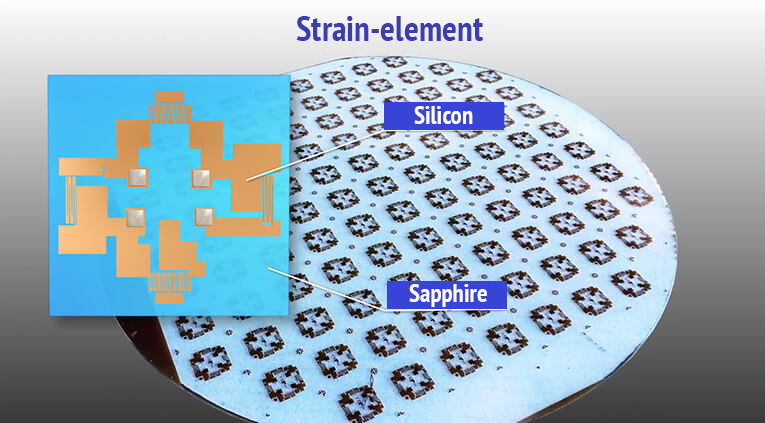

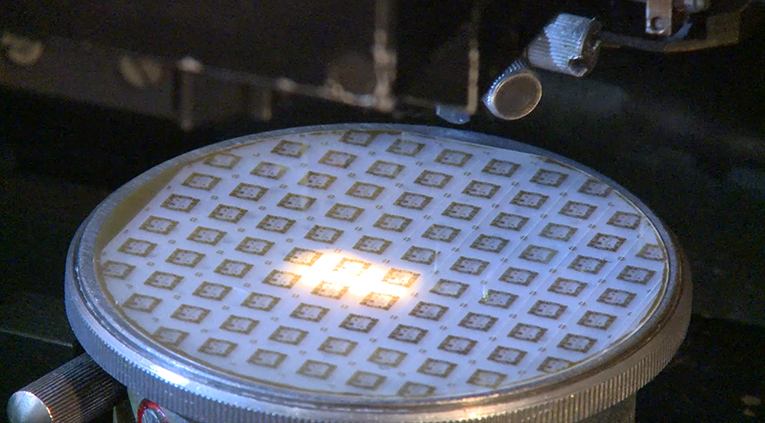

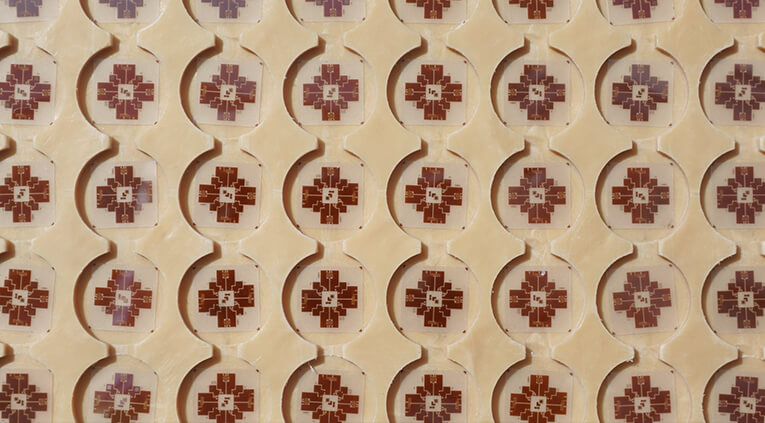

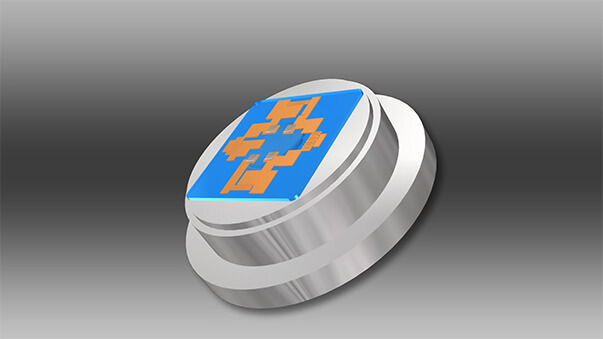

Strain-sensitive elements are manufactured in groups by solid-state microelectronic methods and provide high quality and good repeatability of the output parameters.

Fig. 3 - Strain-elements

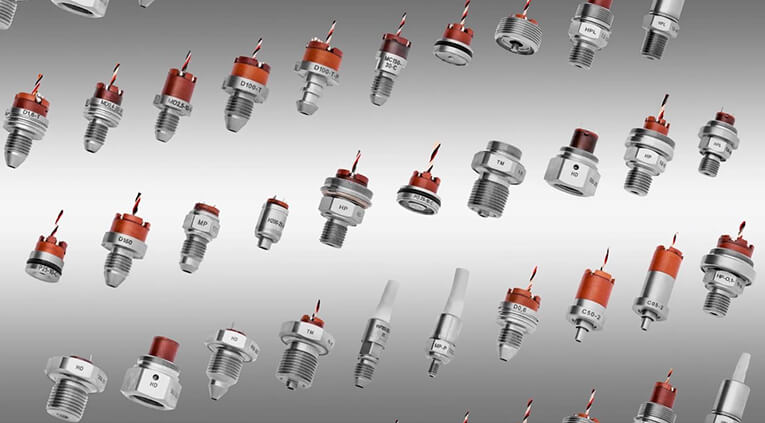

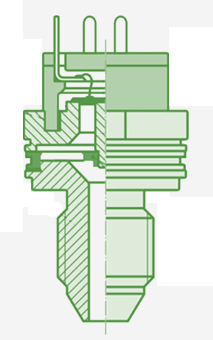

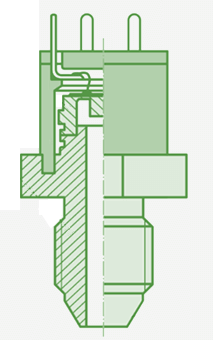

Microtensor manufactures double-diaphragm, single diaphragm welded pressure sensors and one-piece sensors with single diaphragm (Fig.4).

Fig. 4 - Body types of pressure sensors

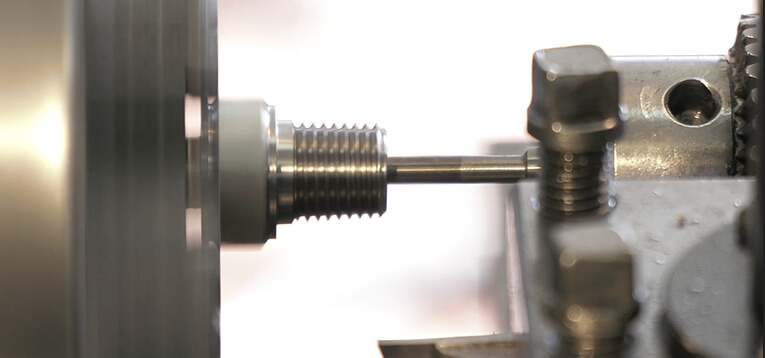

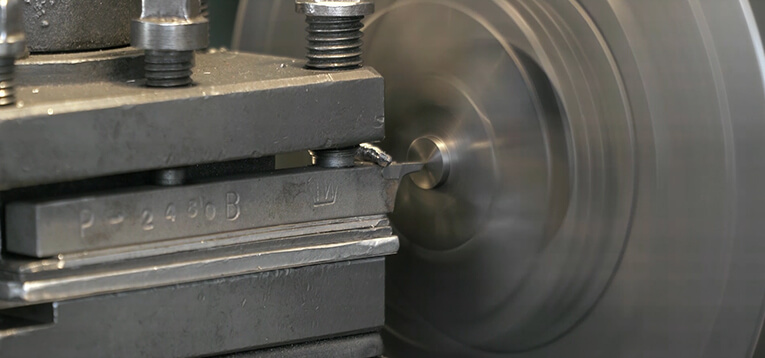

Fig. 5 - Manufacture of bodies and diaphragms

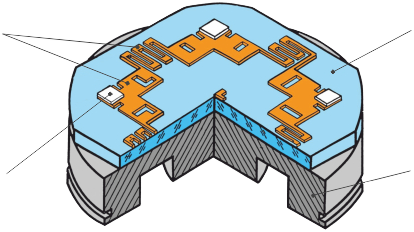

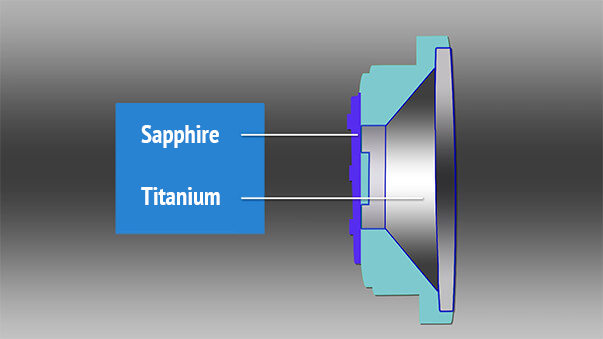

Manufacture of double layer sapphire–titanium diaphragm

Double layer sapphire–titanium diaphragm consists of strain-element with strain gauge Wheatstone bridge and

aluminum bonding pads and titanium diaphragm (Fig. 6.1 and 6.2).

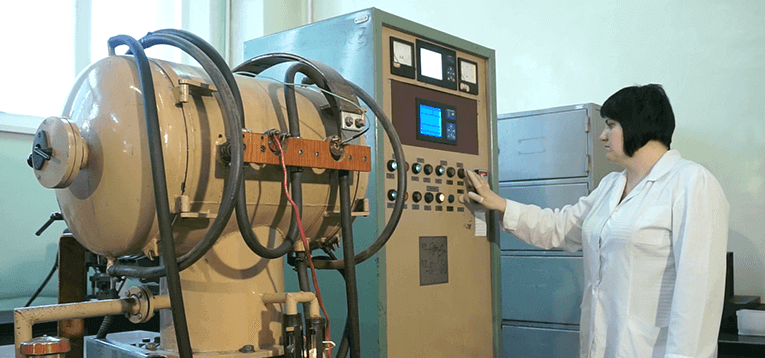

Two diaphragms are connected in vacuum at high temperature (Fig.7).

Wheatstone bridge

Aluminum

bonding pads

Monocrystal

sapphire diaphragm

Titanium diaphragm

Fig. 6.1 - Double layer sapphire–titanium diaphragm

Fig. 6.2 - Double layer sapphire–titanium diaphragm

Fig. 7 - Connection of strain-element with diaphragm or titanium alloy body

High quality of products and lead time are provided by highly experienced staff of about 100 employees.

Fig. 8 - Mictrotensor’s staff

Microtensor manufactures more than 12 series of pressure sensors. If it is needed, pressure sensors can be designed at customer’s request.

All products are represented in “Catalog” section.